📌 TOPINDIATOURS Hot ai: Ultra-fast shipbuilding tool cuts US submarine planning ti

The US Navy is spending $448 million to create a new digital system for American shipyards. Leaders say this will accelerate the adoption of artificial intelligence and automated technologies in the country’s maritime industry.

Secretary of the Navy John Phelan announced the initiative, known as the Shipbuilding Operating System (Ship OS), during the Department of the Navy’s first Rapid Capabilities Office Industry Day.

He was joined by Palantir Technologies CEO Alex Karp, whose company will provide the software foundation for the new system.

From 160 hours to 10 minutes

“This investment provides the resources our shipbuilders, shipyards, and suppliers need to modernize their operations and succeed in meeting our nation’s defense requirements,” Phelan said.

“By enabling industry to adopt AI and autonomy tools at scale, we’re helping the shipbuilding industry improve schedules, increase capacity, and reduce costs. This is about doing business smarter and building the industrial capability our Navy and nation require.”

Ship OS is designed to serve as a unified, data-driven management system that integrates information from enterprise resource planning tools, legacy databases, and real-time production systems.

Navy officials say the platform will help identify bottlenecks, streamline engineering workflows, and provide early warnings on schedule and material risks.

The program is being overseen by the Maritime Industrial Base (MIB) Program in coordination with the Naval Sea Systems Command.

The initial rollout will focus on the submarine industrial base, which has struggled with delays and material shortages as the Navy pushes to expand production of the Columbia- and Virginia-class submarines.

Pilot projects have already produced notable results, Navy officials said. At General Dynamics Electric Boat, Ship OS tools cut submarine schedule planning from roughly 160 manual hours to less than 10 minutes.

At Portsmouth Naval Shipyard, material review times, historically measured in weeks, dropped to under an hour.

“These early outcomes show what’s possible when AI is integrated directly into shipbuilding operations,” a Navy official said.

“We’re seeing efficiency, accuracy, and throughput gains that were not achievable with traditional processes.”

US Navy’s Ship OS

The Navy intends for the system to expand beyond submarine construction after the first phase.

Service leaders said the broader rollout will be “systematic,” guided by lessons learned from the submarine industrial base and tailored to future surface combatant programs.

That includes next-generation destroyers and amphibious ships that will form the backbone of the fleet in the coming decades.

The service emphasized that Ship OS is more than a software installation; it is a long-term industrial reform effort.

The Navy expects measurable cost savings through reduced delays, improved schedules, and better supply-chain visibility.

Officials say those gains are critical as the United States seeks to grow its fleet while competing with China’s rapidly expanding naval shipbuilding sector.

The initiative comes as shipyards across the United States face rising demand, workforce shortages, and aging infrastructure.

Congress has repeatedly pressed the Navy to improve oversight and accelerate production timelines, particularly for submarines.

By providing a common digital framework, Navy leaders say Ship OS will help shipyards modernize their operations and improve coordination with thousands of suppliers.

The program also aims to reduce risk by giving decision-makers real-time visibility across complex production lines.

The launch marks a significant step in what the Navy characterizes as a sweeping effort to revitalize the nation’s maritime industrial base while driving technological innovation.

“This is about ensuring America can build the fleet it needs,” Phelan said. “Ship OS is a major part of that future.”

🔗 Sumber: interestingengineering.com

📌 TOPINDIATOURS Hot ai: World-first 3-in-1 system that merges tidal power, batteri

The European Marine Energy Centre (EMEC) has successfully completed a world-first demonstration that integrated tidal power, long-duration battery storage, and hydrogen production into a single coordinated energy system.

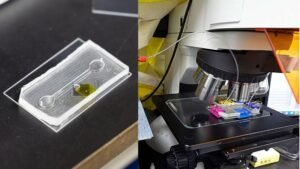

The trial brought together Orbital Marine Power’s O2 tidal turbine, Invinity Energy Systems’ vanadium flow batteries (also called vanadium redox batteries) as well as ITM Power 670-kilowatt (kW) electrolyzer for the first time.

The test was carried out at the center’s accredited research site on the island of Eday in Scotland’s Orkney Archipelago, one of the world’s leading hubs for clean-energy innovation.

“HIE and Scottish Government are pleased to have supported the deployment of innovative technologies at EMEC which have combined in this ground-breaking demonstration,” Graeme Harrison, Highlands and Islands Enterprise’s head of marine energy, said.

Three-tech integration

While each technology has been tested independently before, this was the first time they were operated as a unified system capable of balancing fluctuating tidal generation, storing excess energy, and producing green hydrogen on demand.

Leonore Van Velzen, EMEC’s operations and maintenance manager, revealed that the demonstration marks the culmination of years of work to seamlessly integrate tidal energy, battery storage, and hydrogen production.

“Bringing together three innovative technologies was a complex challenge, but reaching this milestone has provided invaluable insights,” Van Velzen continued.

Credit: Colin Keldie

The researchers tested several energy flow scenarios. Power from the O2 charged the battery system and supplied electricity directly to the electrolyzer during high-generation periods. Any remaining energy was then exported to the grid.

Meanwhile, when tidal generation was low, the battery system discharged power to the electrolyzer to keep it operating. The approach helped smooth out tidal power’s natural cycles.

Moreover, it ensured a steady supply of electricity for the electrolyzer to produce hydrogen. What’s more, battery power was used to support operations at EMEC’s onshore Caldale site.

A unified power system

According to EMEC, this was the first time ever that tidal power, vanadium flow battery storage, and hydrogen production technologies have been integrated into a single energy system.

The team said this approach could help ease future grid constraints and unlock new offtake opportunities, and potentially pave the way for more resilient and responsive renewable energy systems.

“Running all planned scenarios, responding swiftly to an electrolyzer trip and identifying opportunities for greater automation have given us a clear roadmap for optimizing future systems,” Van Velzen elaborated.

Credit: EMEC

In addition to the planned operating scenarios, the researchers tested extra safety measures, including a rapid response to an electrolyzer trip, that prevented a full site shutdown. These measures also proved effective.

While the trial confirmed that the 3-in-1 setup works, it highlighted areas needing further refinement, including battery management and electrolyzer controls. It emphasized the importance of increased automation to improve overall reliability.

“Building on our practical experience with hydrogen, we’re now exploring other offtake routes such as synthetic fuel production using renewable hydrogen as a feedstock, a practical solution to decarbonize hard-to-electrify sectors like aviation and maritime,” Velzen concluded in a press release.

The demo was part of the Interreg North-West Europe–funded ITEG project. It was also supported by the Scottish Government via Highlands and Islands Enterprise, along with the EU-funded FORWARD2030 project

🔗 Sumber: interestingengineering.com

🤖 Catatan TOPINDIATOURS

Artikel ini adalah rangkuman otomatis dari beberapa sumber terpercaya. Kami pilih topik yang sedang tren agar kamu selalu update tanpa ketinggalan.

✅ Update berikutnya dalam 30 menit — tema random menanti!