📌 TOPINDIATOURS Hot ai: When dirt meets data: ScottsMiracle-Gro saved $150M using

How a semiconductor veteran turned over a century of horticultural wisdom into AI-led competitive advantage

For decades, a ritual played out across ScottsMiracle-Gro’s media facilities. Every few weeks, workers walked acres of towering compost and wood chip piles with nothing more than measuring sticks. They wrapped rulers around each mound, estimated height, and did what company President Nate Baxter now describes as “sixth-grade geometry to figure out volume.”

Today, drones glide over those same plants with mechanical precision. Vision systems calculate volumes in real time. The move from measuring sticks to artificial intelligence signals more than efficiency. It is the visible proof of one of corporate America’s most unlikely technology stories.

The AI revolution finds an unexpected leader

Enterprise AI has been led by predictable players. Software companies with cloud-native architectures. Financial services firms with vast data lakes. Retailers with rich digital touchpoints. Consumer packaged goods companies that handle physical products like fertilizer and soil were not expected to lead.

Yet ScottsMiracle-Gro has realized more than half of a targeted $150 million in supply chain savings. It reports a 90 percent improvement in customer service response times. Its predictive models enable weekly reallocation of marketing resources across regional markets.

A Silicon Valley veteran bets on soil science

Baxter’s path to ScottsMiracle-Gro (SMG) reads like a calculated pivot, not a corporate rescue. After two decades in semiconductor manufacturing at Intel and Tokyo Electron, he knew how to apply advanced technology to complex operations.

“I sort of initially said, ‘Why would I do this? I’m running a tech company. It’s an industry I’ve been in for 25 years,’” Baxter recalls of his reaction when ScottsMiracle-Gro CEO Jim Hagedorn approached him in 2023. The company was reeling from a collapsed $1.2 billion hydroponics investment and facing what he describes as “pressure from a leverage standpoint.”

His wife challenged him with a direct prompt. If you are not learning or putting yourself in uncomfortable situations, you should change that.

Baxter saw clear parallels between semiconductor manufacturing and SMG’s operations. Both require precision, quality control, and the optimization of complex systems. He also saw untapped potential in SMG’s domain knowledge. One hundred fifty years of horticultural expertise, regulatory know-how, and customer insight had never been fully digitized.

“It became apparent to me whether it was on the backend with data analytics, business process transformation, and obviously now with AI being front and center of the consumer experience, a lot of opportunities are there,” he explains.

The declaration that changed everything

The pivot began at an all-hands meeting. “I just said, you know, guys, we’re a tech company. You just don’t know it yet,” Baxter recalls. “There’s so much opportunity here to drive this company to where it needs to go.”

The first challenge was organizational. SMG had evolved into functional silos. IT, supply chain, and brand teams ran independent systems with little coordination. Drawing on his experience with complex technology organizations, Baxter restructured the consumer business into three business units. General managers became accountable not just for financial results but also for technology implementation within their domains.

“I came in and said, we’re going to create new business units,” he explains. “The buck stops with you and I’m holding you accountable not only for the business results, for the quality of the creative and marketing, but for the implementation of technology.”

To support the new structure, SMG set up centers of excellence for digital capabilities, insights and analytics, and creative functions. The hybrid design placed centralized expertise behind distributed accountability.

Mining corporate memory for AI gold

Turning legacy knowledge into machine-ready intelligence required what Fausto Fleites, VP of Data Intelligence, calls “archaeological work.” The team excavated decades of business logic embedded in legacy SAP systems and converted filing cabinets of research into AI-ready datasets. Fleites, a Cuban immigrant with a doctorate from FIU who led Florida’s public hurricane loss model before roles at Sears and Cemex, understood the stakes.

“The costly part of the migration was the business reporting layer we have in SAP Business Warehouse,” Fleites explains. “You need to uncover business logic created in many cases over decades.”

SMG chose Databricks as its unified data platform. The team had Apache Spark expertise. Databricks offered strong SAP integration and aligned with a preference for open-source technologies that minimize vendor lock-in.

The breakthrough came through systematic knowledge management. SMG built an AI bot using Google’s Gemini large language model to catalog and clean internal repositories. The system identified duplicates, grouped content by topic, and restructured information for AI consumption. The effort reduced knowledge articles by 30 percent while increasing their utility.

“We used Gemini LLMs to actually categorize them into topics, find similar documents,” Fleites explains. A hybrid approach that combined modern AI with techniques like cosine similarity became the foundation for later applications.

Building AI systems that actually understand fertilizer

Early trials with off-the-shelf AI exposed a real risk. General-purpose models confused products designed for killing weeds with those for preventing them. That mistake can ruin a lawn.

“Different products, if you use one in the wrong place, would actually have a very negative outcome,” Fleites notes. “But those are kind of synonyms in certain contexts to the LLM. So they were recommending the wrong products.”

The solution was a new architecture. SMG created what Fleites calls a “hierarchy of agents.” A supervisor agent routes queries to specialized worker agents organized by brand. Each agent draws on deep product knowledge encoded from a 400-page internal training manual.

The system also changes the conversation. When users ask for recommendations, the agents start with questions about location, goals, and lawn conditions. They narrow possibilities step by step before offering suggestions. The stack integrates with APIs for product availability and state-specific regulatory compliance.

From drones to demand forecasting across the enterprise

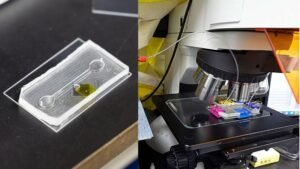

The transformation runs across the company. Drones measure inventory piles. Demand forecasting models analyze more than 60 factors, including weather patterns, consumer sentiment, and macroeconomic indicators.

These predictions enable faster moves. When drought struck Texas, the models supported a shift in promotional spending to regions with favorable weather. The reallocation helped drive positive quarterly results.

“We not only have the ability to move marketing and promotion dollars around, but we’ve even gotten to the point where if it’s going to be a big weekend in the Northeast, we’ll shift our field sales resources from other regions up there,” Baxter explains.

Consumer Services changed as well. AI agents now process incoming emails through Salesforce, draft responses based on the knowledge base, and flag them for brief human review. Draft times dropped from ten minutes to seconds and response quality improved.

The company emphasizes explainable AI. Using SHAP, SMG built dashboards that decompose each forecast and show how weather, promotions, or media spending contribute to predictions.

“Typically, if you open a prediction to a business person and you don’t say why, they’ll say, ‘I don…

Konten dipersingkat otomatis.

🔗 Sumber: venturebeat.com

📌 TOPINDIATOURS Hot ai: 1,360-pound NUMO ground robot deployed by Ukraine to suppo

Designed to minimize the risks faced by troops on the frontlines, Ukraine’s NUMO ground robot features a modular design that accommodates a range of attachments, from turrets and relay masts to wire cutters and mine-clearing equipment. This flexibility allows it to perform multiple roles while keeping soldiers out of harm’s way.

Developed by Lviv-based autonomous systems company Tank Bureau, NUMO can carry up to 661 pounds of cargo and weighs 1,367 pounds when fully loaded.

The system can be deployed in under 10 minutes, features a 9-inch ground clearance, and is capable of navigating challenging terrains such as forests, wetlands, and concealed positions, making it a versatile asset for modern combat operations.

Multiple communications and combat roles

Established in 2024, Tank Bureau specializes in designing and producing unmanned ground vehicles, operating its own research, manufacturing, and maintenance facilities throughout Ukraine. The company has announced plans to expand its lineup, aiming to introduce several additional robotic platforms by the end of the year.

The NUMO ground robot offers extended operational flexibility, with a range of up to 16 miles on two batteries and 28 miles on four, reaching speeds of 4 miles per hour. The vehicle supports six communication systems – Wi-Fi, DTC, Silvus, Starlink, LTE, and SineLink – with a maximum control range of roughly 4,921 feet. It also features the “Droid Box” module, a combined hardware and software suite that enables optional communication capabilities.

NUMO also forms the base of the Droid TW reconnaissance and assault system, equipped with either a KT-7.62 (PKT) or M2 Browning 12.7mm machine gun. The Droid TW-12.7 variant, co-developed by Tank Bureau and DevDroid, is currently deployed across 30 Ukrainian brigades.

Ground robots can deliver, evacuate, and operate in danger zones

Nazar Priymak, director of Tank Bureau, explained that ground robotic systems are designed to take on tasks traditionally handled by soldiers, including delivering supplies, performing evacuations, and operating in environments that are too dangerous for humans.

Priymak also explained that NUMO is already being successfully deployed by the military in active missions, and its formal codification underscores the system’s proven operational readiness and practical value on the battlefield.

Additionally, Ukraine has already fully integrated the DELTA battlefield management system across all levels of its Armed Forces, allowing commanders to coordinate operations more efficiently and track battlefield developments in real time. Since its deployment, the system has verified over 130,000 destroyed or damaged enemy targets, providing critical intelligence for ongoing operations and helping optimize resource allocation.

Earlier this year, Ukrainian assault forces carried out what they claim to be the world’s first fully unmanned offensive operation, capturing Russian troops using only ground robots and aerial drones. The operation took place in the Kharkiv region of eastern Ukraine, representing a milestone in the deployment of autonomous and remotely operated systems in frontline combat.

🔗 Sumber: interestingengineering.com

🤖 Catatan TOPINDIATOURS

Artikel ini adalah rangkuman otomatis dari beberapa sumber terpercaya. Kami pilih topik yang sedang tren agar kamu selalu update tanpa ketinggalan.

✅ Update berikutnya dalam 30 menit — tema random menanti!