📌 TOPINDIATOURS Breaking ai: Single string pull turns flat designs into 3D structu

Researchers at MIT have developed a new way to design 3D structures that deploy from a flat form with a single pull of a string.

The method could help engineers rapidly assemble complex structures in places where speed and portability matter most, including disaster zones.

The technique allows a structure to ship flat, deploy smoothly into a curved 3D shape, and return to its original form when the string is released.

That reversibility could reduce transport costs while enabling fast setup in emergencies, such as deploying a temporary field hospital after a tsunami.

From flat to formed

The new method begins with a user-designed 3D shape.

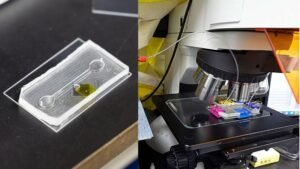

An algorithm then converts that shape into a flat layout made of interconnected tiles.

Each tile connects through rotating hinges, allowing the structure to fold and unfold without rigid assembly steps.

The system calculates how a single string should pass through the structure.

It identifies key lift points and finds the shortest path that minimizes friction.

When a user pulls the string, the structure moves smoothly into its final 3D form.

If the user releases the string, the structure flattens again. That feature allows repeated deployment without damage or reassembly.

“The simplicity of the whole actuation mechanism is a real benefit of our approach. The user just needs to provide their intended design, and then our method optimizes it in such a way that it holds the shape after just one pull on the string,” says Akib Zaman, an electrical engineering and computer science graduate student and the paper’s lead author.

Inspired by kirigami

The researchers drew inspiration from kirigami, the Japanese art of paper cutting.

They divided each design into a grid of quadrilateral tiles that behave as an auxetic structure. Auxetic materials grow thicker when stretched and thinner when compressed.

This geometry helps the structure move predictably during deployment. It also allows the string to guide the shape without motors or complex hardware.

The team faced a major challenge while modeling friction inside the string channel. Early physical tests revealed that boundary tiles needed closure for reliable deployment.

The researchers later proved this behavior mathematically.

They then used a classical physics equation to calculate friction and optimize the string’s path. That process ensured smooth motion with minimal force.

“Our method makes it easy for the user. All they have to do is input their design, and our algorithm automatically takes care of the rest,” Zaman says.

The system works at many scales. The researchers tested it on small medical devices, including a splint and a posture corrector.

They also built a human-scale chair and an igloo-like portable structure.

Because the method does not depend on a specific fabrication process, designers can produce structures using 3D printing, CNC milling, or molding.

Hinges can use flexible materials, while other parts remain rigid.

The approach could support foldable robots that flatten to enter tight spaces.

It may also help engineers design modular space habitats that robots could deploy on Mars.

The research team presented the work at the Association for Computing Machinery’s SIGGRAPH Asia conference.

In future studies, they plan to explore self-deploying versions that do not require humans or robots to pull the string.

For now, the work points toward a simple idea with broad impact: complex structures do not always need complex assembly.

The study is published in the journal ACM Digital Library.

🔗 Sumber: interestingengineering.com

📌 TOPINDIATOURS Hot ai: Disney’s Robot Olaf Is a Straight Up Nightmare Hari Ini

Disney’s robot of its character “Olaf” is incredibly impressive.

It’s also kind of terrifying.

This weekend, engineers at Disney Research Hub published a paper describing how they brought the beloved talking snowman from the “Frozen” films to life as a walking robot — and boy did they succeed.

In a video explaining their work, you can see footage of the robot Olaf, true to its size in the movies, roaming around a Disney park and the lab.

To describe it as uncanny would be harsh, since it does near-perfectly emulate pretty much everything about the character, down to its subtle waddle. But you are left with the distinct impression that what you’re seeing shouldn’t be physically possible; you wouldn’t expect someone with the eyes and proportions of an anime character to step in the real world, and it’s much the same for a 3D-animated snowman. And yet here it is, waltzing before your eyes. You may no longer want to build a snowman ever again, for fear of it coming alive like this one has.

All that aside, it’s a remarkable feat of engineering. You couldn’t get something more true to the character if you shrunk a person and stuck them in an Olaf-suit. You can yoink off the robot snowman’s carrot nose, and it’ll gasp and cackle. It’ll casually smile and wave at you as it ambles by.

The robot posed an unusual challenge to the engineers, who were tasked with building no mere humanoid. It has a huge head the size of its torso supported by a tiny neck, and no visible legs — just feet.

Nonetheless, they prevailed. With the legs, for example, the team concealed most of the lower limbs inside its snowball torso, leaving just the feet showing.

But simply having the robot take short little steps wasn’t enough. They meticulously fine-tuned its gait to mimic Olaf’s from the movie, and in particular ensured it walked with a heel-to-toe pattern to make it as fluid as possible.

To fine tune the robot’s movements, the engineer trained it in a virtual environment using a technique known as reinforcement learning, in which the robot’s AI is rewarded based on it achieving a specific objective across thousands of simulations.

Perfectionists through and through, the team used the technique to reduce the noise of the bot’s steps. No loud plodding for our stout snowman; after implementing some “impact reduction,” the bot’s footfalls dropped from nearly 82 dB in volume to just 64 dB. Even neck temperature was a consideration: since the neck contained a host of small actuators controlling the head, it was at risk of overheating. With reinforcement learning, the bot’s AI system learned to slightly adjust its posture to prevent a thermal buildup, thereby preventing the illusion of animation from melting before our eyes.

More on robots: Robots Tear Up Stage as Backup Dancers

The post Disney’s Robot Olaf Is a Straight Up Nightmare appeared first on Futurism.

🔗 Sumber: futurism.com

🤖 Catatan TOPINDIATOURS

Artikel ini adalah rangkuman otomatis dari beberapa sumber terpercaya. Kami pilih topik yang sedang tren agar kamu selalu update tanpa ketinggalan.

✅ Update berikutnya dalam 30 menit — tema random menanti!